LabV – The Data Management Platform

Quality Control

Reduce waste, react faster.

With LabV you save up to 30% processing time and detect material and production errors more quickly.

Without any effort.

Common issues in quality control

Manual data entry

Fragmented data

Lack of a standardized data structure

Lack of overview on data, projects and historical data

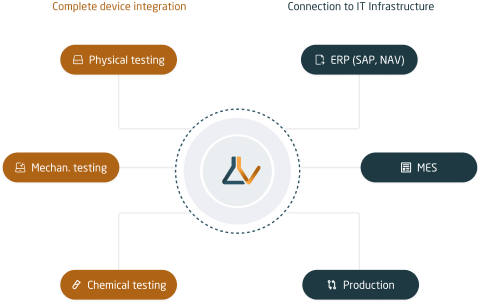

The solution - complete integration of devices and IT infrastructure

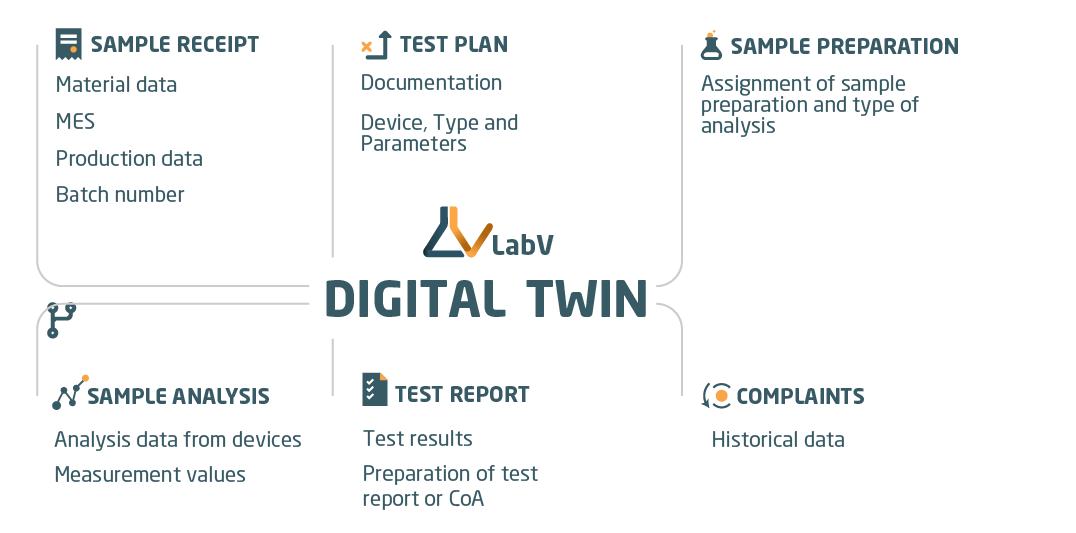

- Digital twin of each sample thanks to a central database

- Fully inter-connected database - from the analytical results through to test portocols and IT infrastructure

- Efficient management of all test orders

- Ki-assisted evaluation of complex search queries in a comprehensive data pool

“Fewer tests means fewer engineering hours and faster development. With LabV we have a saving of 10% in engineering hours”

Development Manager

|

Manufacturer of paints and coatings

The solution - one single database for everything

Our features

- A central database for laboratory and material development

- Efficient communication and collaboration

- Individual connection to devices, MES, ERP and IT infrastructure

- User-friendly interface for company-wide acceptance

- Quick recognition of connections and correlations

- AI-enabled data infrastructure for evaluating complex search queries in a comprehensive data pool

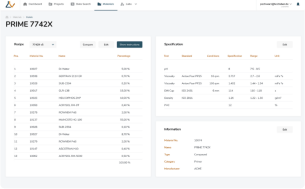

Managing

- Complete and cross-funcitional connection of all devices and the existing IT infrastructure

- Collected data from laboratory and development

- Management of testing orders and analyses

Analyzing

- Fast data evaluation with integrated statistical functions and visualizations

- Centralized material database

- Automated comparison of target values and actual results

- Identification of correlations and relationships

Exploiting

- More insightsacross the entire database

- Comprehensive search function

- AI-enabled data infrastructure for intelligent predictions on product properties and recipes

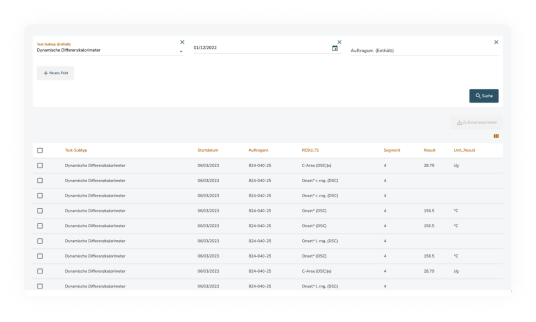

Example - Trend identification at your fingertips

LabV allows to identify trends and correlations much easier and quicker than ever before, maximizing the utility of the data pool. Detecting anomalies earlier means less waste and more efficiency.

WHITE PAPER

Digitalization - step by step

Learn in the white paper:

- The implications of inadequate digitalization on quality assurance labs

- The differences between LIMS, CAQ and data management systems for materials testing laboratories

- Proposed solutions to overcome Excel and paper and to ensure data integrity

- How companies can systematically start their digitization journey