LabV – The Data Management Platform

MATERIAL DEVELOPMENT

Eliminate duplicate effort, develop products faster.

With LabV you reduce the development of new materials and discover trends and correlations that were previously unknown.

All that with no effort and in no-time.

The issues in material development

Duplicated efforts thanks to fragmented data and missing insights

Chaotic data structure, so that correlations and trends remain unrecognized

Lack of a consistent and standardized data structure

The solution - one single database for everything

Without LabV

Data from process and application engineering in the technical center and test laboratory is transferred manually. The result: a lack of transparency, duplicated work and unnecessarily extended development times.

With LabV

With LabV, everything is in one database that can be accessed by both the technical center at process engineering and the testing laboratory. The outcome: a clear overview, better collaboration and faster recognition of correlations in development.

“Fewer tests means fewer engineering hours and faster development. With LabV we have a saving of 10% in engineering hours”

Development Manager

|

Manufacturer of paints and coatings

Our features

- A central database for laboratory and material development

- Efficient communication and collaboration

- Individual connection to devices, MES, ERP and IT infrastructure

- User-friendly interface for company-wide acceptance

- Quick recognition of connections and correlations

- AI-enabled data infrastructure for evaluating complex search queries in a comprehensive data pool

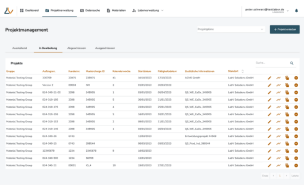

Managing

- Complete and cross-funcitional connection of all devices and the existing IT infrastructure

- Collected data from laboratory and development

- Management of testing orders and analyses

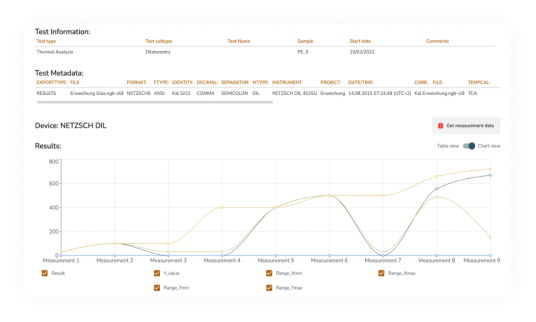

Analyzing

- Fast data evaluation with integrated statistical functions and visualizations

- Centralized material database

- Automated comparison of target values and actual results

- Identification of correlations and relationships

Exploiting

- More insightsacross the entire database

- Comprehensive search function

- AI-enabled data infrastructure for intelligent predictions on product properties and recipes

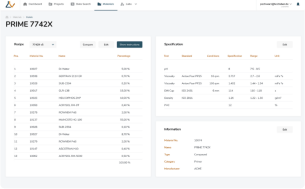

Example - material database

The material database contains all target values that can be viewed by the laboratory and pilot plant at the touch of a button. Important information for optimizing the product parameters in the technical centre, and the target values in the laboratory, which can be automatically compared with the measured values. Increased efficiency

Blog Post

The Digital Twin in Material Development

For many companies, the days of handwritten records and Excel are still the norm. However, digitalization could enable new approaches in industrial material development. Companies that have taken the plunge know this.